Chicken farms in Southeast Asia are huge, and more and more farmers are aware that sustainable agriculture is becoming more and more important, especially in the Philippines, where there are many large farms and face greater challenges in managing chicken manure accumulation and reducing odor diffusion!

Retech Farming is a poultry farming equipment manufacturer from China. After visiting many farms, we developed energy-saving fermentation tanks for chicken houses, which help to create a sustainable agricultural environment and contribute to environmental protection!

Challenges of chicken manure accumulation

If you have raised chickens or lived near a farm, you must know a series of problems caused by chicken manure accumulation:

1. The unpleasant smell will attract flies and affect the living environment;

2. Chicken manure accumulates inside and outside the farm, occupying farm land resources. If not handled in time, it will cause harm to the chicken house and affect the health of the chickens;

3. Traditional manure treatment methods are labor-intensive and costly;

If managed properly, chicken manure is a valuable resource, so how to effectively deal with pollutants in the chicken house?

Retech’s energy-saving fermentation tank, 1 fermentation tank can treat the manure of 100,000 chickens, easily solving the problem of manure docking in large farms.

4 Benefits of Energy-saving Chicken Manure Fermenters

1. Effective Waste Management

Energy-saving fermentation tanks promote the decomposition of chicken manure through anaerobic digestion. This process converts waste into biogas and organic fertilizer, greatly reducing the amount of manure and minimizing the impact on the environment.

2. Reduce Odor

Closed fermentation tanks ferment chicken manure more efficiently, significantly reducing the unpleasant odors produced by traditional manure management methods. This improvement not only improves the working environment for farm workers, but also helps to create a healthier environment for nearby communities.

3. Comply with local environmental regulations

As environmental regulations become increasingly stringent, the use of energy-saving fermentation tanks can help farmers comply with local laws on waste management and odor control. This not only protects the environment, but also improves the farm’s reputation among consumers and regulators.

4. Enhance soil health

The organic fertilizer produced during the fermentation process is rich in nutrients. Using it for crops can improve soil health and increase crop yields. Secondary use after fermentation can increase farm profits

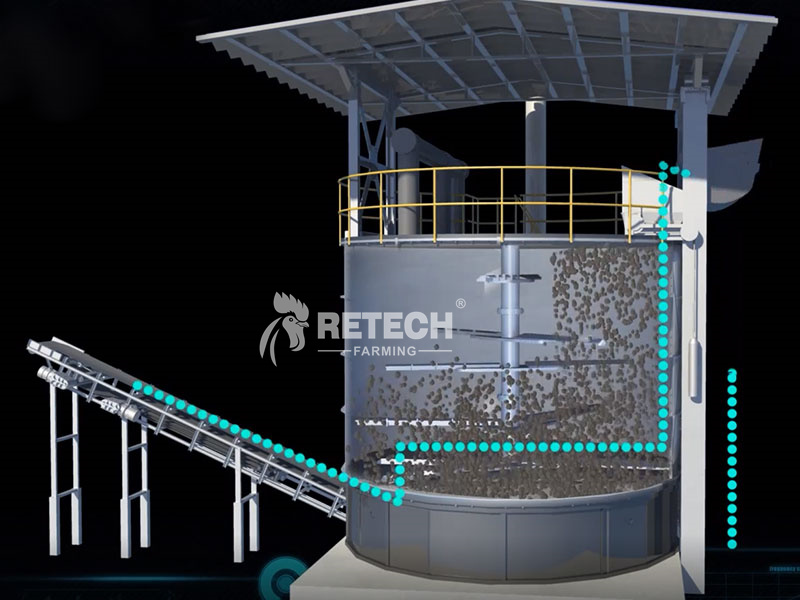

The fermentation process in a fermenter

The fermentation process in a fermenter involves several key steps that help break down organic matter (such as chicken manure) into useful products (such as biogas and organic fertilizer). Here is a brief overview of the process:

1. Feedstock Preparation

The first step is to prepare the chicken manure. This may include mixing the manure with water to form a slurry, which helps optimize fermentation conditions.

2. Loading the Fermenter

Once the feedstock is prepared, it is loaded into the fermenter. The fermenter is designed to maintain specific environmental conditions that are conducive to anaerobic digestion, such as temperature, pH, and moisture content.

3. Anaerobic Digestion

In the anaerobic environment of the fermenter, microorganisms (bacteria) begin to break down the organic matter. This process is divided into several stages:

Hydrolysis: Complex organic matter is broken down into simpler compounds.

Acidification: These simpler compounds are further converted into volatile fatty acids, hydrogen, and carbon dioxide.

Acetogenesis: Volatile fatty acids are converted into acetic acid, while producing more hydrogen and carbon dioxide.

Methanogenesis: Finally, methanogenic bacteria convert acetic acid and hydrogen into methane (CH4) and carbon dioxide (CO2), creating biogas.

4. Biogas Collection

As the fermentation process progresses, biogas accumulates in the upper part of the fermenter. This biogas, which is mainly composed of methane, can be collected and used to produce energy.

5. Digestate Removal

After the fermentation process is complete, the remaining solid material, called digestate, is removed from the fermenter. Digestate is nutrient-rich and can be used as an organic fertilizer for crops and enhances soil health.

6. Monitoring and Control

Throughout the fermentation process, various parameters such as temperature, pH, and gas production are monitored and controlled to ensure optimal conditions for microbial activity and maximum biogas production.

Manure organic fertilizer fermenters are a sustainable agricultural solution for chicken farms in the Philippines, addressing the issues of manure accumulation and environmental pollution. By investing in a fermenter, pollutant management within the chicken house can be improved and soil health can be enhanced. The benefits are not limited to the farm; there is a positive impact on the entire community and environment. It is also in line with the environmental protection concept advocated by the Environmental Protection Department.

If you would like to learn about Retech’s project cases in the Philippines, please contact me!

Email: director@farmingport.com

Post time: Dec-16-2024