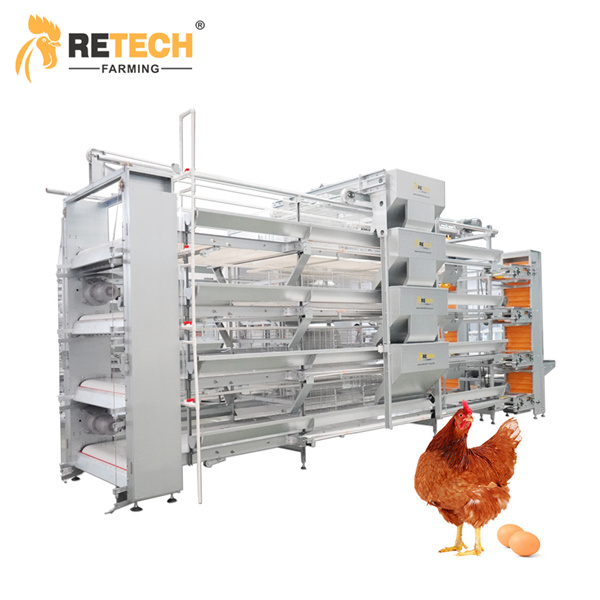

Automated Chicken Egg Cage Solutions from Leading Manufacturers

When I think about efficiency and productivity in poultry farming, the Chicken Egg Cage stands out as a game-changer. These automated systems are designed to optimize egg production while ensuring the welfare of your chickens. As a manufacturer, I know how crucial it is to streamline operations and reduce labor costs; these cages do just that! With features that enhance nesting comfort and promote cleanliness, the Chicken Egg Cage not only increases yield but also helps in maintaining quality eggs. Trust me, having a reliable setup can significantly impact your bottom line. Plus, the ease of installation and maintenance makes it a smart investment for any serious farmer. If you're ready to take your poultry operation to the next level, integrating an automated Chicken Egg Cage can be the solution you're looking for. Let’s boost productivity and simplify your farming journey together!

Chicken Egg Cage Ahead of the Curve Now Trending

In the rapidly evolving agricultural industry, innovation is key to ensuring productivity and sustainability. One of the latest trends making waves globally is the advancement of chicken egg cages, which have been recognized for their efficiency and ability to meet the growing demand for eggs. These modern cages are designed to enhance the well-being of hens while optimizing space and resources for farmers. By integrating cutting-edge technology, they not only improve egg production rates but also promote healthier living conditions for the birds. The spotlight on these advanced chicken egg cages signifies a shift towards more humane and efficient farming practices. With features such as adjustable environments, automated feeding systems, and enhanced monitoring capabilities, these cages cater to the diverse needs of both farmers and animals. As global consumers increasingly prioritize ethically sourced products, embracing these trends can give farmers a competitive edge and bolster their market presence. For buyers seeking reliable sourcing solutions, investing in innovative and sustainable chicken egg cages ensures a commitment to quality and efficiency. As the poultry industry continues to expand, adapting to these trends is crucial for meeting consumer demands and achieving long-term success. Embracing cutting-edge technology today positions businesses strategically for the challenges of tomorrow, ensuring they remain ahead of the curve in a competitive market.

Chicken Egg Cage Ahead of the Curve Now Trending

| Dimension | Value |

|---|---|

| Average Egg Production (per Hen per Year) | 280 Eggs |

| Cage Size (L x W x H) | 24 x 18 x 18 inches |

| Material Type | Galvanized Steel |

| Density of Hens per Cage | 5 Hens |

| Egg Collection System | Automatic |

| Average Feed Conversion Rate | 2.25 kg Feed/kg Eggs |

| Lighting System | LED Lights |

| Ventilation Type | Natural & Mechanical |

Related Products