Automatic Battery Cage System in Poultry | Leading Manufacturer Insights

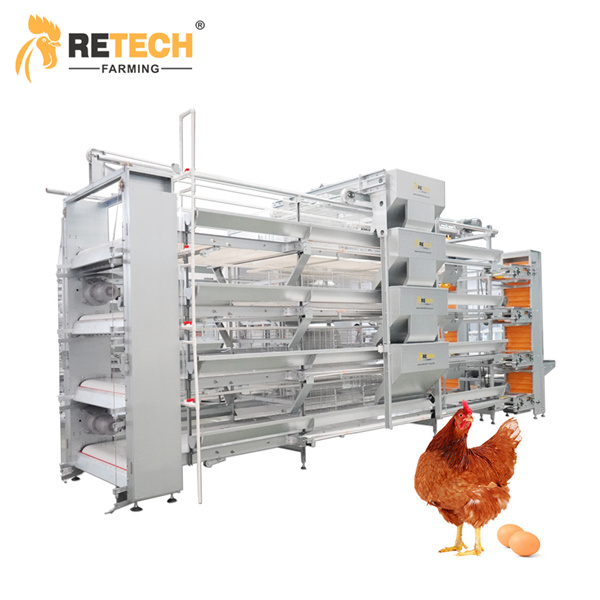

Are you in the market for an efficient battery cage system in poultry that enhances productivity? Our automatic solutions are designed to streamline egg production, ensuring a consistent supply while prioritizing the health and welfare of your birds. As a manufacturer, we understand the specific needs of poultry businesses, and our systems are crafted to deliver optimal performance. Imagine reducing labor costs and improving efficiency with our innovative, easy-to-use automatic battery cage systems. You’ll appreciate the durability and reliability of our products, designed to withstand the rigors of day-to-day operations. Our focus is on providing high-quality solutions that meet the demands of both small farms and large-scale poultry operations. Connect with us to explore how our battery cage systems can transform your business, maximize your output, and support sustainable practices in poultry farming. Let’s drive your success together with our expert solutions!

Battery Cage System In Poultry Application Ahead of the Curve

In the ever-evolving poultry farming industry, the battery cage system emerges as a pivotal innovation for optimizing production and ensuring animal welfare. This advanced system provides a controlled environment that maximizes space and efficiency while allowing for better management of flock health. With a design that prioritizes the well-being of hens, the battery cage system minimizes stress levels and promotes natural behaviors, contributing to higher egg production and improved quality. Global buyers seeking reliable solutions in poultry farming should consider the benefits of adopting the battery cage system. Not only does it facilitate automated feeding, lighting, and waste management, but it also aligns with international standards for humane animal treatment. The compact design maximizes the use of available space, making it ideal for both large-scale and small-scale operations. By investing in this cutting-edge technology, poultry farmers can enhance their productivity, reduce operational costs, and meet the growing demand for sustainably produced eggs. As the poultry industry moves towards greater sustainability and efficiency, incorporating the battery cage system is a proactive step for any forward-thinking enterprise. It allows for real-time monitoring and data collection, enabling farmers to make informed decisions that improve their overall operations. Embracing such innovations not only positions businesses ahead of the competition but also aligns them with the global trend toward responsible farming practices.

Battery Cage System In Poultry Application Ahead of the Curve

| Parameter | Value | Unit |

|---|---|---|

| Cage Size | 18 | cm x 45 cm |

| Bird Density | 12 | birds per cage |

| Feed Conversion Ratio (FCR) | 1.5 | kg feed / kg egg |

| Average Egg Production | 280 | eggs per year |

| Mortality Rate | 5 | % |

| Water Consumption | 0.2 | L/bird/day |

| Space Requirement | 0.5 | m²/bird |

| Egg Size | Large | (≥ 63g) |

Related Products